A well-structured safety program is crucial for maintaining a safe work environment and ensuring compliance with OSHA regulations. Companies must maintain proper documentation to demonstrate their commitment to workplace safety and protect themselves in the event of an audit or incident. Safety documentation is the foundation of a comprehensive safety program. These materials ensure that everyone, from new hires to seasoned supervisors, understands the procedures and responsibilities that maintain a safe workplace. Every industry benefits from having clear, accessible safety documentation. Below is a breakdown of the 10 essential documents every company should include in its safety program.

Site Safety Professional

The Vital Role of a Site Safety Professional in Project Success

Ensuring the safety of workers, visitors, and the surrounding community is paramount in any construction or industrial project. A commitment to safety fosters a positive work environment and ensures successful and profitable construction projects with safety as their foundation. Site safety professionals play a pivotal role in upholding this commitment. A qualified site safety professional can support your construction project through multifaceted means. These skilled experts are dedicated to implementing safety protocols, monitoring hazards, and promoting a genuine safety culture throughout the project’s lifecycle. Their expertise encompasses a range of essential functions that contribute to the safety of the construction or industrial site. Site safety professional oversight extends to providing impartial third-party assessments, offering valuable assurance and accountability throughout construction. The unique value that a qualified and certified construction safety professional brings to a project cannot be overstated. The presence of a qualified and certified construction site safety professional instills confidence in workers and contractors alike.

Welding Safety: Protecting Lives from Hazards

Welding Safety: Protecting Lives from Hazards

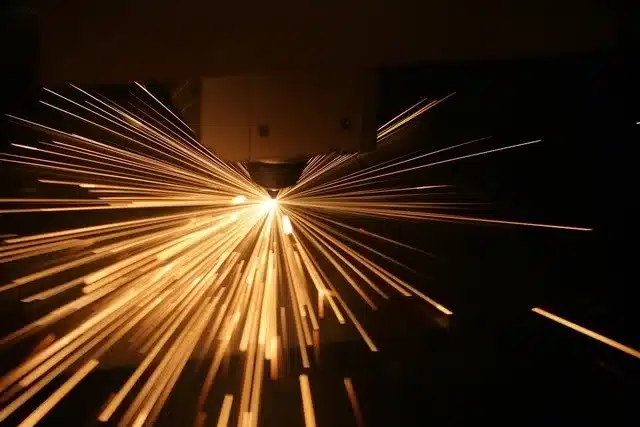

Welding, the process of joining metals through intense heat and melting, is a fundamental technique in construction, manufacturing, and various industries. While it plays a pivotal role in shaping our world, it’s essential to remember that welding involves inherent risks that can pose dangers to experienced professionals and novices alike. April is National Welding Month, a good opportunity to review the critical aspects of welding safety and highlight the precautions welders should take to ensure their safety and well-being.

3 Reasons to Invest in Safety Training Today

In 1970, the Occupational Safety and Health Act was signed into law and in April 1971, the Occupational Safety and Health Administration (OSHA) issued the first standards for workplace safety. Similarly, the Mining Enforcement and Safety Administration was established in 1973, which lead to the creation of the Mine Safety and Health Administration (MSHA) in 1978. Since then, safety training has been a fundamental part of every safety and health program. OSHA’ s Construction, General Industry, Maritime, and Agricultural standards require that employers provide their employees with a safe workplace and that safety training is provided in a language and vocabulary that workers can understand. MSHA develops and enforces safety and health rules for all mines in the United States and sets regulations for the required safety training and safety plans related to the mining industry.

Safe + Sound Week

Safe + Sound Week will be held August 15-21, 2022 and all are welcome to participate. This nationwide event offers information and ideas focused on keeping America’s workers safe. It is an excellent opportunity to recognize your organization’s commitment to safety and health, build upon your current safety program or start the process of developing your own safety and health program.

Benefits of On Site Safety Managers

10 Benefits of Hiring an Environmental Health and Safety Professional

Hiring a third-party Environmental Health and Safety (EHS) professional for your next construction project provides significant advantages to your organization. Our site safety construction managers offer the credentials and experience you need and focus on keeping your employees safe.

Preventing Heat Related Injuries

Summer is upon us and with it comes an increased risk of heat related injuries to workers who must work outdoors. Many of the injuries and fatalities that occur due to heat, happen in the first few days of working in the warm or hot temperatures. Heat stroke, heat exhaustion and heat cramps can result from the rising temperatures if precautions are not taken. Employers have a duty to provide a safe workplace free of health and safety hazards, including heat related hazards. OSHA has launched a National Emphasis Program (NEP) on outdoor and indoor heat hazards which will remain in effect for three years unless cancelled or extended.

National Safety Stand – Down: May 2-6, 2022

This year, the National Safety Stand-Down will take place the week of May 2-6, 2022. This yearly event is designed to raise awareness about the risks of fall hazards. Falls remain a leading cause of workplace deaths each year and fall protection is one of the most frequently cited OSHA citations. Results of a fall hazard can lead to death, serious injuries, paralysis, broken bones, blunt trauma to the head and internal damage. Deaths and injuries can be prevented by planning ahead to get the job done safely. Employers are required to provide the correct fall protection equipment and train all workers to use the equipment effectively. The National Safety Stand-Down is an opportunity to ensure fall hazard risks are reduced or eliminated and train workers on this hazard.

Six Key Elements to Developing a Positive Safety Culture

A positive safety culture at your organization is good business practice. It’s beneficial to both management and employees and something all businesses should strive to achieve. Having one is important, but getting one is not always an easy task. It can take time to develop and apply the fundamental elements of a positive safety culture at your organization. However, once these six key elements are part of your safety program, your business will reap the benefits of a safe, productive, thriving workplace.

March is Ladder Safety Month: 10 Ladder Do’s and Don’ts

March is National Ladder Safety Month and an excellent opportunity to raise awareness about how to safely work around a common tool, found in almost every home and at many job sites. Often, ladder safety training can be inadequate because it is assumed that ladders are simple to use, compared to the more complex equipment such as cranes, forklifts and other power and handheld tools employees must use at construction sites. However, it is not only construction workers who use ladders on the job. Firefighters, building inspectors, electricians, painters, maintenance workers, power line installers and certain mechanics may be required to use a ladder for their daily tasks. Each year, too many people are injured or die as a result of unsafe work on or around ladders. Injuries caused by improper ladder use, falls from ladders and electrocution due to not using the correct type of ladder are preventable. Workers need to be educated and properly trained on the dangers that can arise when working on or around ladders for your job site to remain injury free.