Welding Safety: Protecting Lives from Hazards

Welding, the process of joining metals through intense heat and melting, is a fundamental technique in construction, manufacturing, and various industries. While it plays a pivotal role in shaping our world, it’s essential to remember that welding involves inherent risks that can pose dangers to experienced professionals and novices alike. April is National Welding Month, a good opportunity to review the critical aspects of welding safety and highlight the precautions welders should take to ensure their safety and well-being.

Understanding the Risks:

Welding involves high temperatures, bright sparks, and the potential to release hazardous fumes and gases. Too many workers die or become injured each year due to welding-related accidents. Some of the risks associated with welding include:

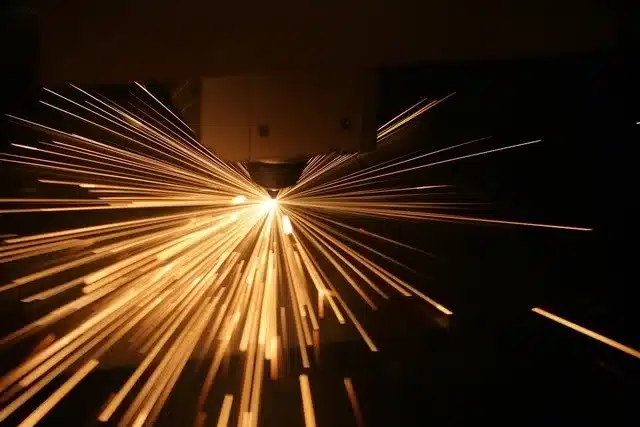

- Arc Flash: Arc flash is a hazardous phenomenon commonly associated with welding. Welding generates intense heat and electrical currents, creating an arc between the welding electrode and the workpiece. This arc produces intense ultraviolet radiation, sparks, and molten metal particles, posing significant risks to welders and nearby personnel. Arc flash incidents can result in severe burns, eye damage, and even fatalities if proper safety measures are not observed.

- Arc Radiation: The intense light produced during welding, known as arc radiation, emits harmful ultraviolet (UV) and infrared (IR) rays. Prolonged exposure can lead to skin burns and even long-term damage to the eyes.

- Fume Emissions: Welding fumes consist of fine particles and gases that can contain toxic elements like manganese, chromium, and nickel. Inhaling these fumes can result in respiratory issues, lung diseases, and other health complications.

- Electrical Hazards: Welding involves high currents and voltages, which can lead to electric shock or electrocution if safety measures are not followed.

- Fire and Explosion: The intense heat generated during welding can ignite flammable materials nearby. Additionally, sparks and hot metal fragments can create fire hazards.

- Compressed Gas Hazards: Welding often requires compressed gases, which can be hazardous if improperly handled. Leaks or mishandling can lead to explosions or asphyxiation.

- Physical Injuries: Physical injuries during welding are common and often include cuts, crushed fingers and toes, and eye damage. Welding involves using sharp tools, heavy equipment, and molten metal, making workers susceptible to cuts and abrasions from sharp edges and flying debris. Crushed fingers and toes are also prevalent due to the heavy machinery and materials involved in welding. Additionally, the intense light and radiation emitted during welding can cause severe eye damage if proper eye protection is not worn.

- Noise Exposure: Noise exposure during welding poses a significant occupational hazard, as the process typically generates high levels of noise that can lead to hearing damage and impairment if proper precautions are not taken. The intense sound produced during welding operations arises from various sources, including the electric arc, gas flow, and equipment vibrations. Continuous exposure to these loud noises can result in temporary or permanent hearing loss, tinnitus, and other auditory disorders. Additionally, the frequency and intensity of the noise depend on factors such as welding technique, equipment used, and the surrounding environment.

Precautions for Safe Welding:

To ensure a safe working environment and reduce the risks associated with welding, welders should follow a comprehensive set of safety precautions:

- Good Housekeeping: Good housekeeping during welding is important for safety, efficiency, and quality outcomes. Maintaining a clean and organized workspace reduces the risk of accidents and promotes optimal welding conditions. Proper storage of welding equipment, tools, and materials prevents clutter and ensures quick access when needed. Regular removal of debris from work surfaces and surrounding areas minimizes tripping hazards. By prioritizing good housekeeping practices, welders create an environment that enhances productivity and contributes to the overall integrity of their work.

- Protective Clothing and Gear (PPE): Wear flame-resistant clothing, leather gloves, a welding helmet with proper shading for eye protection, and appropriate footwear. Depending on the welding process, aprons and respiratory masks are also necessary. To mitigate the risks associated with noise exposure, welders should wear appropriate hearing protection devices, such as earplugs or earmuffs, and employers should implement engineering controls and noise reduction strategies to minimize sound levels in the workplace. Regular monitoring of noise levels and employee training on hearing conservation practices are essential to ensure the safety and well-being of welders.

- Ventilation: Ensure proper ventilation in the work area to prevent the accumulation of harmful fumes and gases. If working indoors, consider using local exhaust ventilation systems. Implementing effective ventilation systems helps mitigate the health risks associated with welding fumes.

- Eye and Face Protection (PPE): Always wear a welding helmet with the appropriate shade lens to protect your eyes from intense light and sparks. Safety glasses with side shields should be worn under the helmet for additional eye protection.

- Respiratory Protection: If working in environments with potential fume exposure, wear a respirator approved for welding fumes to prevent inhaling hazardous particles and gases.

- Training and Certification: Only trained and certified welders should perform welding tasks. Proper training ensures knowledge of equipment operation, safety protocols, and emergency procedures.

- Electrical Safety: Inspect welding equipment regularly for damaged cords or faulty connections. Use dry gloves and wear insulated footwear to prevent electric shock.

- Fire Prevention: Clear the work area of flammable materials and keep a fire extinguisher within reach.

- Safe Handling of Gases: Store and handle compressed gases properly, following manufacturer guidelines. Keep cylinders secured and away from open flames or high temperatures.

- Maintain Equipment: Maintaining and inspecting all equipment before use can prevent injuries.

- Limit Exposure: Minimize the time spent near the welding arc to reduce the risk of arc radiation exposure. Use remote controls or automation where possible.

- Regular Health Checkups: Undergo regular medical checkups to monitor your respiratory health and overall well-being, especially if you’re regularly exposed to welding fumes.

Welding is a skill that merges creativity with technical precision, but it’s crucial to prioritize safety alongside craftsmanship. By understanding the potential risks and implementing rigorous safety measures, welders can shield themselves from harm while producing high-quality work. Vigilant adherence to protective clothing, proper ventilation, and safety equipment are the cornerstones of welding safety, which is paramount in any industrial or construction setting. The inherent risks associated with welding processes demand a comprehensive approach to ensure workers’ well-being. At Safety Consulting Specialists, we understand the critical importance of maintaining safe working conditions during welding projects.

Do you need assistance to ensure safe working conditions for your welding projects? Our experienced safety team is dedicated to providing tailored solutions that address the specific requirements of your welding operations. We offer various services to mitigate risks and promote safety throughout your organization. Training is a cornerstone of our approach to welding safety. Our team delivers comprehensive training programs that equip your workforce with the knowledge and skills necessary to identify hazards, implement safe practices, and respond effectively to emergencies. In addition to training, our experts conduct thorough site safety audits to identify potential hazards and areas for improvement. By partnering with Safety Consulting Specialists, you can have confidence in the safety and well-being of your workforce. Contact us today at 919-417-2139 to discuss how we can tailor our services to meet your welding safety needs.