The Importance of PPE in Workplace Safety

Personal Protective Equipment (PPE) plays a crucial role in workplace safety and is a fundamental element of any comprehensive safety program. Its importance lies in protecting workers from various occupational hazards and reducing the risk of injuries, illnesses, and even fatalities. Tailored for specific workplace risks, PPE encompasses specialized equipment that protects individuals from potential workplace hazards. The required types of PPE can vary depending on the specific industry, job tasks, and potential risks. Many OSHA standards require the employer to provide PPE to their employees. Serving as the ultimate safeguard, PPE constitutes workers’ last line of defense. Here are the key reasons why PPE is essential for workplace safety:

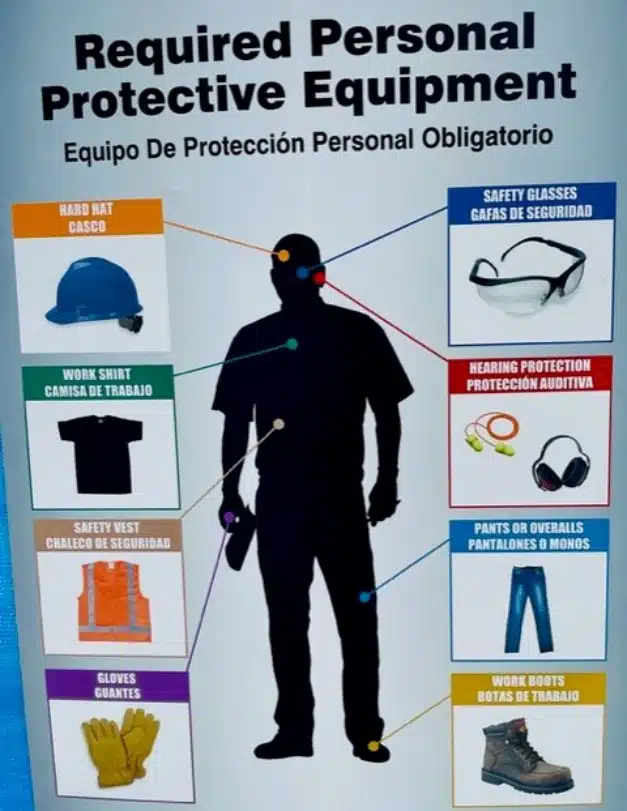

- Hazard Protection: PPE is a barrier between workers and various workplace hazards. It includes equipment such as helmets, safety glasses, gloves, respirators, earplugs, and more, each designed to address specific risks like falling objects, chemical splashes, respiratory hazards, noise, etc.

- Injury Prevention: By providing protection against potential hazards, PPE helps prevent injuries to the head, eyes, ears, hands, feet, and other body parts. This is particularly crucial in high-risk industries like construction, manufacturing, and mining, where the risk of accidents and injuries is higher.

- Respiratory Protection: Respiratory hazards, such as harmful dust, fumes, gases, and airborne pathogens, can cause serious respiratory illnesses. Respirators are essential PPE to protect workers’ lungs from these hazardous substances, especially in environments with poor air quality.

- Infection Control: In healthcare settings, PPE like masks, gowns, and gloves are critical in preventing the spread of infectious diseases among healthcare workers and patients. During outbreaks or pandemics, widespread use of PPE can help contain the spread of contagious illnesses.

- Compliance with Regulations: Many occupations’ health and safety regulations and standards mandate using PPE in specific work environments. Employers are legally required to provide and ensure the proper use of PPE to protect workers from identified hazards.

- Confidence and Productivity: When workers feel safe and protected, it boosts their confidence, leading to increased productivity and better job satisfaction. Knowing that their employer prioritizes their safety fosters a positive work environment.

- Emergency Preparedness: In emergency response situations, such as firefighting or hazardous material handling, specialized PPE is essential for protecting responders from immediate dangers.

- Risk Reduction: While engineering controls and administrative measures are preferable for hazard mitigation, they may not always be feasible. PPE serves as a vital secondary control measure, reducing the risk of exposure to hazards.

- Preventing Long-Term Health Issues: Prolonged exposure to certain hazards can lead to chronic health problems, such as hearing loss, respiratory disorders, and skin diseases. Proper use of PPE prevents or minimizes the impact of such long-term health issues.

- Contractor and Visitor Safety: PPE is not only for employees; it is also necessary to protect contractors, visitors, and anyone else entering the workplace who may be exposed to hazards.

While the modern concept of PPE use in workplace safety emerged during the 20th century, earlier forms of protective equipment were used to address specific risks. In ancient times, soldiers wore armor made of leather, metal, or other materials to protect themselves from weapons and projectiles. In the 19th century, workers in mines used cloth masks or scarves to protect themselves from inhaling dust or other airborne particles. Early forms of PPE were a step toward recognizing the importance of protection but were limited in their effectiveness and sophistication. Today, PPE, which meets strict safety standards, has significantly improved worker protection and workplace safety. Here is a list of common types of PPE for workplace safety:

- Head Protection: Constructed from durable materials, such as rigid plastics and impact-resistant polymers, hard hats and helmets protect against falling objects, overhead hazards, and accidental bumps. Their innovative design incorporates suspension systems that help absorb and distribute impact forces, reducing the risk of skull fractures and traumatic brain injuries. Whether on construction sites, industrial facilities, or hazardous environments, wearing properly fitted hard hats and helmets is not just a matter of compliance but a proactive step towards safeguarding the well-being of workers and ensuring they can carry out their duties confidently.

- Eye and Face Protection:

- Safety glasses-Safety glasses are the most basic form of eye protection and are suitable for protecting against impacts from flying particles, dust, and debris. They typically have impact-resistant lenses and side shields.

- Goggles-Safety goggles provide a more comprehensive seal around the eyes, protecting against chemical splashes, vapors, and potential airborne hazards. They create a barrier between the eyes and the surrounding environment.

- Face shields-Face shields cover the entire face to provide protection against high-velocity impact hazards, chemical splashes, and other potentially hazardous substances. They are used in combination with safety glasses or goggles, not instead of.

- Welding helmets-Welding helmets are specialized face protection designed to shield against harmful radiation, intense light, and sparks generated during welding and related processes.

- Hearing Protection: Wearing appropriate hearing protection is essential in maintaining workplace safety and preventing potential long-term hearing damage due to prolonged exposure to loud noises.

- Earplugs

- Earmuffs

- Noise-canceling headphones

- Respiratory Protection: Respiratory protection is worn to protect against harmful airborne contaminants.

- Dust masks

- N95 respirators

- Half-face or full-face respirators

- Powered air-purifying respirators (PAPRs)

- Supplied Air Respirator Systems (SAR)

- Self-Contained Breathing Apparatus (SCBA)

- Hand Protection: Utilizing proper hand protection, such as gloves, is crucial for ensuring workplace safety by reducing the risk of injuries and safeguarding against potential hazards or contaminants.

- Gloves (various types, such as leather, rubber, chemical-resistant, cut-resistant)

- Gauntlets

- Foot Protection: Foot protection protects workers from crushing, piercing, cutting, and slipping.

- Safety shoes

- Steel-toed boots

- Metatarsal guards

- Chemical-resistant boots

- Body Protection: Effective body protection shields workers from various workplace hazards, promoting overall safety and minimizing potential injuries.

- Coveralls

- Aprons

- Chemical-resistant suits

- High-visibility vests

- Flame-resistant clothing

- Fall Protection: Implementing fall protection measures in the workplace is paramount for preventing accidents, safeguarding workers at heights, and maintaining a secure environment that prioritizes their well-being.

- Safety harnesses

- Lanyards

- Fall arrest systems

- Anchorage points

- Personal Fall Protection System (PFPS)

- Heat and Cold Protection: Utilizing specialized heat and cold personal protective equipment (PPE) is essential for safeguarding workers against extreme temperature conditions, ensuring their well-being and productivity in diverse workplace environments.

- Thermal clothing

- Insulated gloves

- Heat-resistant gloves

- Cooling vests

- Chemical and Biological Protection: Proper utilization of chemical and biological personal protective equipment (PPE) is imperative for shielding workers from hazardous substances, toxins, and pathogens, effectively minimizing the risk of exposure and ensuring a safe working environment.

- Chemical-resistant suits

- Respirators with specific filter cartridges

- Gloves and aprons resistant to chemicals and biohazards

- Electrical Protection: Employing appropriate electrical personal protective equipment (PPE) is vital for safeguarding workers from potential electrical hazards, reducing the risk of shocks and burns, and maintaining a safe work environment in the presence of live electrical systems.

- Insulating gloves

- Voltage-rated tools

- Arc flash suits

- Radiation Protection: Specialized radiation personal protective equipment (PPE) is crucial for minimizing workers’ exposure to harmful radiation sources, ensuring their safety, and preventing potential health risks in environments where radiation is a concern.

- Lead aprons

- Radiation-resistant clothing

- Protective eyewear

- Ergonomic Protection: Incorporating ergonomic personal protective equipment (PPE) into the workplace promotes employee comfort and reduces the risk of musculoskeletal disorders by ensuring proper body mechanics and minimizing strain during tasks.

- Back support belts

- Wrist supports

- Anti-fatigue mats

- Hygiene Protection: Maintaining hygiene through the use of appropriate personal protective equipment (PPE) helps prevent the spread of contaminants, pathogens, and germs in the workplace, promoting a healthier and safer environment for all employees.

- Disposable coveralls

- Hairnets

- Beard covers

- Shoe covers

Determining the proper PPE for the job begins with a hazard assessment. Review OSHA requirements for PPE as set in the Code of Federal Regulations (CFR). OSHA requires many categories of PPE to meet the standards approved by the American National Standards Institute (ANSI). Select the appropriate PPE for the task. Additionally, it’s essential to regularly inspect the PPE for any signs of wear and tear and promptly replace damaged, worn, or expired equipment. Properly train workers on the correct use, care, and maintenance of PPE and ensure proper fit. Most importantly, ensure that management enforces compliance with PPE use.

The importance of PPE in workplace safety cannot be overstated. It complements other safety measures and is critical to an overall safety culture. Employers must provide suitable PPE, ensure proper training on its use, and enforce its use to safeguard workers’ health and well-being.

Feel free to contact Safety Consulting Specialists with any inquiries about the necessary PPE for your workplace. We are here to offer our assistance and are happy to help. Moreover, we offer safety training, equipment inspections, and on-site safety professionals tailored to your construction project. Don’t hesitate to get in touch with us today!