When it comes to safety, do you want to be lucky, or do you want to be good? To be good, you have to avoid complacency every day. Far too many companies rely on luck, and unfortunately, when their luck runs out, the result is often a serious accident resulting in injury, property loss, damage, fines, or worse. If you have worked on a job site, in a manufacturing facility, or held a supervisory role, you have probably heard the following excuses or different versions of them many times.

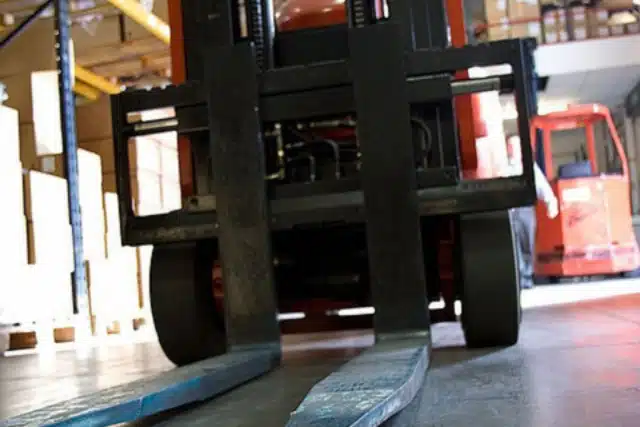

7 Tips for Forklift / Powered Industrial Truck Safety

June 13, 2023, is National Forklift Safety Day and an excellent opportunity to focus on forklift safety. Forklifts, also known as powered industrial trucks, are standard on construction sites, distribution centers, and manufacturing facilities, helping with efficiency. There are many types of powered industrial trucks, each unique. Weighing between 4,000-9,000 pounds, they are versatile equipment for loading and unloading supplies, moving heavy materials, and transporting goods. They are helpful as they combine a lifting tool’s functions with a vehicle’s mobility. However, working on or around forklifts/powered industrial trucks is associated with significant risks. Forklifts pose collision, falls, tip-overs, and struck-by hazards. Safe forklift operation involves proper safety training and proper forklift maintenance.

10 Fall Protection Basics

10 Fall Protection Basics: What You Need to Know

The National Safety Stand-Down to Prevent Falls in Construction will be held May 1-5, 2023. This nationwide event will raise fall hazard awareness. There are several ways to participate in this National Safety Stand-Down, including holding a toolbox talk focused on fall prevention, scheduling a training session about fall protection, or conducting a safety inspection of your fall protection system. It is best to designate someone from your organization to plan and organize your Stand- Down ahead of time and get 100% participation from your team. You can also check www.osha.gov to see events in your area that are free and open to the public. Participation in this event shows a commitment to workplace safety and is an opportunity to ensure fall hazard risks are reduced or eliminated. No company is too small to participate. This week-long event spotlights the dangers of falls, but it is best safety practice to focus on fall protection all year.

Here’s What EMR Means for your Business

EMR Explained.

What is EMR?

Experience modification rating, also called EMR or Experience mod, is a number used by insurance companies to measure risk. It is an insight into a company’s injury rates and measures the past cost of workplace accidents and the future risk of your business compared to others in the same industry and state. Workers’ compensation is a benefit system developed to provide medical coverage and wage replacement for injured employees. EMR significantly impacts the workers’ compensation insurance premium of a company.

Essential Crane Safety Tips

Crane safety is crucial to any construction project or industrial operation involving cranes. Cranes are powerful machines that are used to lift and move heavy materials and equipment. However, their immense size and weight, coupled with the loads they carry, also make them potentially hazardous.

Guide To 120 Environmental, Health, and Safety Abbreviations

Guide To 120 Environmental, Health, and Safety Abbreviations

Abbreviations, acronyms, and initialisms are used daily by safety professionals. Often, it’s assumed that everyone knows what they are talking about or that they are trying to save time by using a shorthand version of the phrase. Abbreviations can simplify communication if you understand them. However, it’s easy to miss key points and get confused when safety jargon leaves you asking, “What does that mean?”. We have compiled this resource of 120 Environmental Health and Safety Abbreviations to help decode the specialized language safety professionals use daily. Being familiar with this safety terminology can help you create a safe workplace. Misunderstanding key terms can put you or your employees at risk. Errors can be made if these abbreviations are mixed up or misinterpreted. Keep in mind that this list is for general purposes only. Please consult the applicable standards or contact us for more information if you have specific questions. We are always available to answer your workplace safety questions and provide guidance on best safety practices. Please reach out to us at 919-417-2139 or We’d love to hear from you!

7 Benefits of Good Housekeeping on your Jobsite

7 Benefits Of Good Housekeeping On Your Jobsite

Construction sites can be dangerous places filled with risks. A messy and disorganized job site poses an even greater risk. Good housekeeping may not seem like it directly relates to the safety of your construction project, manufacturing site, or office space. However, it plays a vital role in a safety program. OSHA recognizes good housekeeping as an essential element of safety and has at least four standards that relate to good housekeeping to prevent things such as tripping over loose objects on the floor, being hit by falling objects, or slipping on wet or dirty surfaces. Of the four standards, three are for general industry, and one is specific to construction sites. OSHA standard 1910.141 for general industry states that all places of employment shall be kept clean to the extent that the nature of the work allows, and OSHA standard 1910.22 walking-working surface standard says that all workplaces should be kept clean and orderly in a sanitary condition. OSHA standard 1910.106 relates to hazardous materials and flammable/combustible liquids, while OSHA standard 1926.25 discusses general housekeeping regulations for construction. Ensuring appropriate housekeeping can help control or eliminate workplace hazards, resulting in a safer work environment.

MSHA

MSHA: What Is It? Who Needs MSHA Training?

MSHA is the acronym for the Mine Safety and Health Administration and is the federal government agency responsible for protecting the health and safety of all U.S. miners. MSHA develops and enforces safety and health rules for all U.S. mines regardless of their size or number of employees. Since its creation, MSHA has had a significant impact on improving the safety of mines. In 1978, 242 miners died in mining accidents. In 2020, that number fell to 29. In 2022, the current number of miners who have died is 27. Contrast that with the fateful day of December 6, 1907, when more than 350 miners were killed when two massive explosions occurred at a mine site in Monongah, West Virginia. Due to that disaster, December 6 is now designated as National Miners Day. National Miners Day is not only a day to commemorate the anniversary of the worst mining accident in American history but to recognize the hard work of miners across this country and to thank them for their essential contributions to our society.

OSHA’s Top 10 Cited Standards for 2022

OSHA has updated its list of the most frequently cited standards for all industries for its fiscal year 2022, which runs from October 1-September 30. Not surprisingly, these are the same standards cited from 2021, only the order of some of the standards has changed. Hazard communication moved up to the number two spot while respiratory protection dropped to the number three spot. Other standards have shifted places within the list, but fall protection remains in the number one position from the previous year.

Protect Your Hearing

Noise has been an occupational hazard for hundreds of years dating back to ancient and medieval times. In those days, city dwellers dealt with noise from carriages on cobblestone streets while craftsmen such as blacksmiths and tinsmiths were exposed to loud sounds while performing their trades.